Preventing Hydraulic Cylinder Failures: Best Practices for System Longevity

- Hydra-Spares

- Jun 25, 2025

- 1 min read

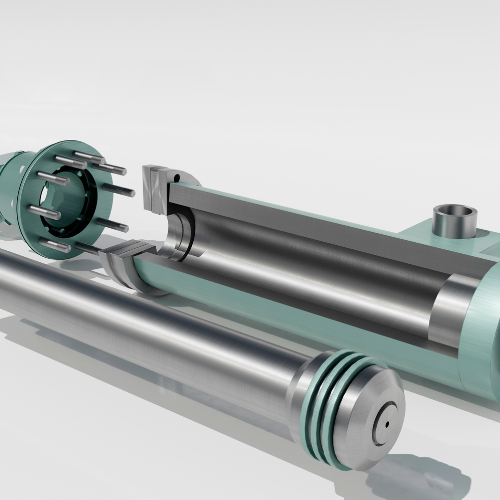

Hydraulic cylinders are at the core of most hydraulic operations, translating hydraulic energy into mechanical force. When they fail, productivity halts. The good news? Most hydraulic cylinder failures are preventable with the right practices — and Hydra-Spares is here to help you prevent them.

The Top 3 Reasons Hydraulic Cylinders Fail

Contaminated Hydraulic Fluid

Dirt, debris, and metal particles are enemies of your hydraulic system. Contaminants scratch cylinder walls, damage seals, and degrade fluid performance. This is why proper filtration and routine fluid changes are non-negotiable.

Seal Wear and Tear

Seals deteriorate with age, high temperature, and chemical exposure. Hydra-Spares offers high-quality seal kits compatible with most OEM specifications to help you maintain pressure and performance.

Mechanical Misalignment or Overloading

Misaligned cylinders or improperly installed rods place uneven stress on components. This accelerates wear and increases the risk of bending or snapping under load.

Preventative Maintenance Tips

Inspect Regularly: Check for leaks, wear, and unusual noises.

Use Correct Lubricants and Fluids: Always follow the manufacturer's specs.

Install with Precision: Make sure cylinders are mounted properly and torqued to spec.

Choose Quality Parts: Hydra-Spares only supplies components we trust and use ourselves.

What We Offer

Seal kits for all major hydraulic brands

Replacement rods, cylinders, and repair parts

Expert guidance from our technical sales team

Fast dispatch from our Cape Town warehouse

Avoid costly downtime — protect your hydraulic investments with Hydra-Spares' expert advice and premium components.

Comments